Top 9 Advantages Of Laser Cutting In Today’s Trend

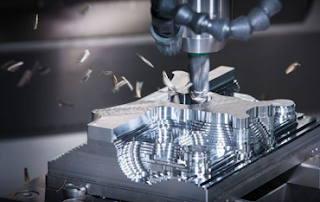

Laser cutting is a cutting-edge technology that utilizes a highly focused laser beam to precisely cut through materials. Unlike traditional cutting methods, such as sawing or shearing, laser cutting in Los Angeles delivers a level of precision that is unmatched, making it an indispensable tool across a myriad of industries. In the ever-evolving landscape of manufacturing and design, one technology has emerged as a true game-changer: laser cutting. This sophisticated process has revolutionized the way materials are shaped and crafted, offering unparalleled precision and versatility. It has use of Metal Parts in Los Angeles which is beneficial. Precision and Accuracy: Laser cutting offers unparalleled precision and accuracy, allowing for intricate and complex designs with microscopic details. This level of precision is crucial in industries where tight tolerances are non-negotiable. Versatility in Material Handling: Laser cutting is versati...