How Does CNC Machining Work?

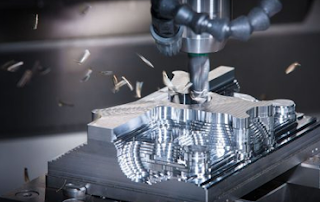

Computer numerical control CNC machine is a manufacturing process that needs to be programmed into computer software that dictates the movement of factory tools and machinery. It is a process which can be used to control a range of complex machinery from the grinder and lathers where mills and CNC routers. It is a three-dimensional cutting task where it is accomplished by a single set of prompts. It is a process which runs in contrast and has limitations with manual control and works with live operators who need to prompt with a guide and command the machine tools. CNC Machining in Los Angeles has the best type of machine.

CNC is a system which has desired cuts programmed into the software and dictated with corresponding tools and machinery with the dimensional task and specified robot. CNC programming is a code generator where it has a numerical system and it assumes the mechanism which flawless, and less possibility of error and is directed to be cut simultaneously. It is a placement tool where numerical control is outlined with a series of inputs with the part of the program.

It is numerical control machining where the program has been inputted with a puch card. Where contrast the program with the CNC machining tool and fed to the computer through the small keyboards. CNC programming is retained with computer memory. It has Metal Part Prototyping where the code itself is written and edited by the programmers. Where the CNC system is expansive computational capacity. It is a system which is static with newer prompts and added existing programs with revised code.

CNC Machine Programming

It is a machine which is aerated with numerical control and a software program which is designed to control objects. It is a language which offers the best CNC Machining in Los Angeles. It has G-codes which is written to control various behaviour like speed, feed rate and coordination.

Open/ Closed Loop Machine System: CNC manufacturing is a position control where it can be determined with an open loop or closed loop system. Where it has signalising run where it has a single direction and it has a CNC controller and motor. It is a closed-loop system where the controller is capable of receiving feedback and error correction possibilities.

It is a tool where you

can turn the position with guided steps an serve motors which can easily

replicate the exact movement and need to be determined by the Code. It has

force and speed with a minimal process and it runs easily on open loop control.

Where everything is closed-loop control and necessary to ensure the speed with

consistency and accuracy is required for industrial application.

Comments

Post a Comment