How CNC Machining Works?

CNC machining, which

stands for Computer Numerical Control machining, is a manufacturing process

that utilizes computer-controlled machine tools to remove material from a work

piece to create precise and complex shapes. It is a highly versatile and widely

used method in the manufacturing industry for producing parts and components

from various materials, including metals, plastics, and composites. CNC

Machining In Los Angeles allows

for high levels of precision, repeatability, and efficiency, making it a

crucial technology in modern manufacturing.

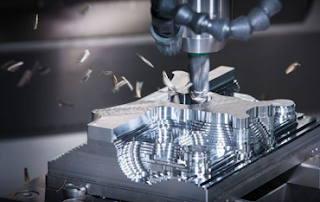

How CNC Machining Works:

Design and Programming: The process begins with the creation of a detailed 3D CAD (Computer-Aided Design) model of the desired part. This digital model serves as the blueprint for the CNC machine to follow. Skilled programmers then write a CNC program that contains step-by-step instructions for the machine to execute.

Material Selection: The choice of material depends on the specific requirements of the part. CNC machining can work with various materials, including metals (such as aluminum, steel, and titanium), plastics, wood, and composites. It is also used in Plastic Injection Molding Manufacturers.

Machine Setup: The CNC machine

operator loads the raw material, known as a work piece, into the machine and

secures it in place. They also load the CNC program, which contains the

instructions for the machining operations.

Tool Selection: Depending on the material and the machining operations required (e.g., milling, drilling, turning, or grinding), appropriate cutting tools are selected and installed in the machine's tool holder.

Machining Operations: The CNC machine follows the programmed instructions to precisely move the cutting tool(s) in multiple axes (typically X, Y, and Z) and remove material from the workpiece. The high degree of automation and precision in CNC machining ensures that the final part matches the design specifications.

Quality Control: During and after machining, quality control measures are often employed to ensure that the part meets the specified tolerances and quality standards. This may include using precision measuring tools and inspection equipment. In the Plastic Injection Molding Manufacturers it has best quality control.

Completion: Once the machining operations are complete, the finished part is removed from the CNC machine, and any necessary finishing or post-processing steps, such as deburring or surface treatment, may be performed to achieve the desired surface finish and functionality.

CNC Machining in Los Angeles is a precise, versatile, and efficient manufacturing process that plays a crucial role in producing high-quality components for a wide range of industries, from aerospace and automotive to electronics and healthcare. Its automation, accuracy, and adaptability have revolutionized modern manufacturing.

Comments

Post a Comment